🔥 The Make-or-Break Moment for Any Optical Cable: INSTALLATION.

A top-tier GYTS cable can still fail if installed poorly. They say it’s “30% product, 70% installation”—here’s how to get that 70% right.

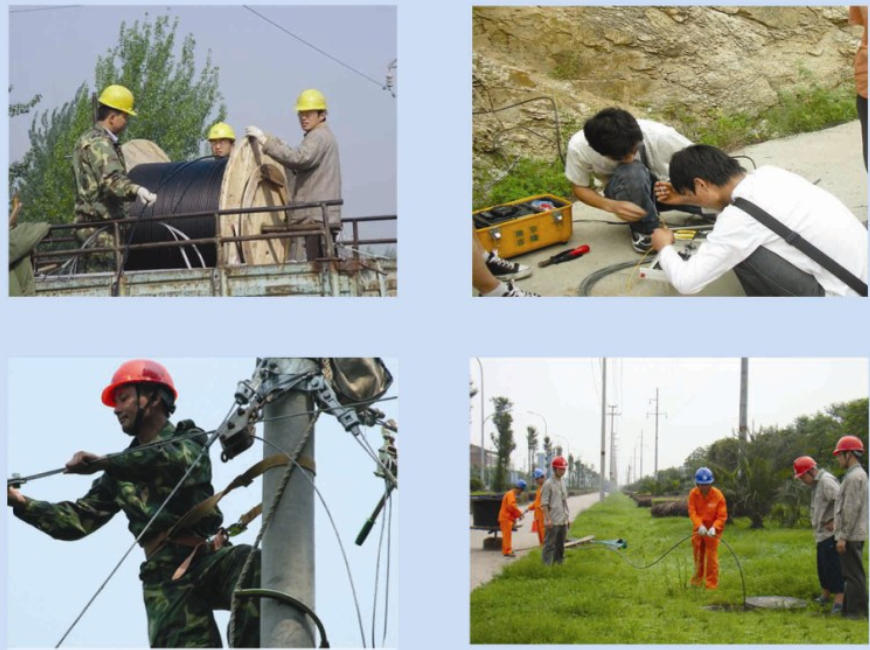

🧱 3 Main Installation Methods & What Matters

| Method | Best For | Key Requirements |

| Duct Installation | Urban underground, tunnels | Clean ducts before pulling. Tension ≤ 1500N. Leave slack in manholes. Use cable markers. |

| Direct Burial | Rural areas, no duct infrastructure | Burial depth: ≥0.8m under roads, ≥0.6m elsewhere. Use flat trench, compact backfill, and warning tape/bricks. |

| Aerial Installation | Existing or new utility poles | Support with messenger wire (max 50m spans). Ensure pole strength, sag control, and safe distance from power lines. |

⚡️ The 3 Non-Negotiable Rules of Installation

No matter the method, these rules are absolute:

➡️ Respect the Bend Radius

Static (after install): ≥ 10x cable diameter.

Dynamic (during install): ≥ 20x cable diameter.

A sharp bend = increased attenuation or broken fibers.

➡️ Never Exceed the Pulling Tension

Pull force must be applied to the central strength member, NEVER the outer sheath or fibers.

Max instantaneous pull force ≤ 100% of cable’s short-term tensile rating (3000N for standard GYTS).

➡️ Splice with Precision

Splices must be inside an IP68-rated closure, sealed with gel and moisture-absorbent packets.

Average splice loss should be < 0.08dB per joint.

🎯 Good installation isn’t just following steps—it’s understanding the why behind every tension limit, every bend radius, and every seal.

Whether you’re an engineer, a project manager, or a technician, respecting the craft of installation ensures the network performs as designed—for decades.

👇 Have you seen a project fail (or succeed) because of installation quality? Share your story below.